Cost is a huge factor in making purchasing decisions – particularly in the construction industry, and even more so in tougher economic times.

This can be a valid reason to choose one supplier over another. But only if you’re comparing the same installation quality and standards.

The problem is, while you might think that you are comparing like with like, you often aren’t. Particularly, if the job requires very high levels of supervision and inspection.

This is especially true in the façade waterproofing industry.

After design, any façade work essentially breaks down to two components: the product and the workmanship.

Mistakenly, it is the product that most people consider when they make their decision. After all, it is much easier to compare product specifications (if you don’t know what you are doing).

What is often not considered is the workmanship part. After all, the sealants or joints aren’t going to apply or install themselves, and a robot can’t do it yet either!

So, while it is important to choose the right products for waterproofing your building’s façade, it is equally important to know the quality of the workmanship you are selecting too.

If two companies are quoting the same product, the difference in their prices will most likely come down to the labour, workmanship, compliance and QA cost.

And, you do get what you pay for.

The right product, poorly applied, will cause you just as many issues and additional costs, as using the wrong product – and the consequences can be significant.

Getting it right first time is cheaper than having the job done twice

It makes sense, right?

A great example is the call we received two Christmases ago.

A large high rise building in the Auckland CBD was leaking. Sansom had actually assisted in the design phase to make sure that what was being built could be constructed and made watertight.

Unfortunately, the tender didn’t go our way and we ended up losing out on price to someone else to do the applicator work correctly.

That work had started but the contractor was unable to provide quality assurance that was meaningful, and they couldn’t keep water out of the building.

Initially, the main contractor thought it was a design issue and they issued a variation to the scope of works at their cost to allow the problem to get fixed, but the applicator still couldn’t keep the water out.

So, they called us, and we were able to go back to the original design and install the waterproofing as we said it should have been able to be done. It then passed all the water tests without issue and remains dry to this day.

In short, some of the job had to be done twice and, while we were more expensive than the first applicator to do the job initially, we were a lot cheaper than the total cost that the main contractor paid in the end. This doesn’t include the damage (both physical and reputational) from water leaking in the meantime.

Overall, the right product was specified to the right places. What went wrong on this job was the inability of our competition to apply the quality of the workmanship required to achieve success.

Anyone can do it, but not anyone should

Unlike with other trades, such as builders, plumbers and electricians, there is no formal qualification to become a waterproofing applicator.

Some suppliers run one day training courses to teach applicators the basics, but this isn’t mandatory, and leaves building owners and main contractors unclear as to what they can expect from applicators.

Therefore, it is up to the company itself to make sure that their applicators are trained in how to correctly apply and install different products.

That is just the base level of knowledge though, what is even more valuable is experience. Not all situations are the same and what can look simple on a drawing, can be a more complicated in practice.

At Sansom, internal training is a real focus and, in addition to having our new applicators do all the relevant supplier trainings, we also pair them up with senior applicators to learn from and be taught how to do things well.

This includes a significant amount of on-the-job training where the new applicator can see what could go wrong and how to circumnavigate issues, identify what looks out of scope, and how to deal with clients and complex situations.

What separates Sansom from other tenderers is that our façade team is only doing façade work all day, every day, so they can really hone their skills and deliver work to the highest standard.

We also pay our applicators by the hour as opposed to using a per metre rate. Therefore, our team is incentivised to do a quality job, compared to effectively being paid for speed (applying the sealant as quickly as possible and then moving on to the next job in order to apply as many metres as possible in a day, which is the case for most other tenderers).

Overall, our considered approach means we can stake our reputation on our workmanship and have confidence that our work will last for the lifespan of the waterproofing system we’ve installed.

Quality assurance for peace of mind

How do you know that the workmanship on waterproofing your building’s façade is up to standard?

Products have warranties issued by the supplier, which cover that the material was manufactured to a specified standard and will perform correctly when used in the right situations.

However, once the product has been sold to the applicator, the responsibility really falls to the applicator to what happens after that, and the supplier of the product doesn’t care who they sell it too.

At this point, everything else comes under “workmanship” and any warranties on the workmanship, come from the applicator themselves. These “workmanship warranties” are only vetted by the main contractor and, if there hasn’t been any proper quality assurance (QA), they may not be worth the paper they are written on.

QA can be requested by the façade engineer or main contractor, and we’ve seen some pretty basic responses out there – from paper checklists to Word documents with a bunch of photos dumped on them and, in some instances, none.

However, since QA is such a critical part of the process, it should be mandatory on every job.

Over the years, we’ve worked with main contactors, engineers and suppliers to develop a comprehensive QA process and output. This all done through software tool, CONQA, which is live and easy to keep up to date and share with all the relevant parties. Our clients often use our QA as part of their submission to Auckland Council for council inspections.

Going one step further, we do random destructive testing on joints that have been completed. We also encourage clients and façade engineers to come along and nominate any random location in the building. We cut out a section of joints and then complete tear testing and adhesion tests, measure how it has been installed, and report back to show that the joints have actually been fitted to the correct dimensions or characteristics as per the specification.

This means our clients don’t need to just take our word that our team has done a good job and installed everything correctly, they can see for themselves the quality of the workmanship and effectiveness of the final result.

Workmanship is a factor you can’t ignore

When it comes to choosing a contractor to waterproof the façade of your building, you must consider the skill and experience of who will be doing the work.

The consequences of not getting it right can be significant and, at a pure cost level, it is always cheaper to get a skilled applicator to do the job right first time, rather than have to pay someone else to come back and redo the work because the façade still isn’t watertight.

Understanding how the applicators are trained is critical and robust QA is vital to make sure you’re not left with headaches, mounting costs and a leaky building.

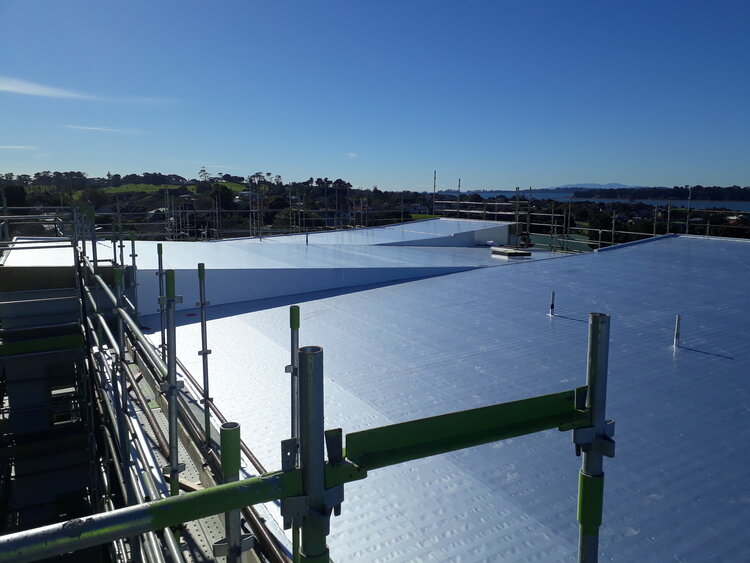

At Sansom, we are a waterproofing company and that is what our clients pay for. We’re unlikely to be the cheapest, but our experienced, skilled team is backed by an efficient structure of support systems (health and safety, QA, and warranties that we back), complementary specialist skills (concrete repairs, tanking and roofing) and qualifications (such as working at heights).

With 130 site staff, 18 dedicated to façade waterproofing alone, we are able to easily complete large scale projects within programme or over multiple small sites concurrently.

So, you get peace of mind that we know what we are doing, will get the job done, and stand behind our work.

Get in touch to start the conversation about your upcoming project. https://www.sansom.co.nz/contact-sansom