First impressions matter – even for buildings.

The structure’s outer shell or façade is the first thing anyone sees when arriving at a building.

However, façades play more than just a cosmetic role in a structure. They are a shield for a building, protecting it from water and moisture – effectively managing water runoff and drainage, and reducing the risks of leaks. A well-designed and built façade ensures structural integrity, building longevity, and perhaps, most importantly, protects against the health risks associated with being in a damp building.

As you can imagine, as building designs become more complex and environmental and seismic factors have to be taken into account, the trickier it can be to waterproof the façade.

Unfortunately, despite its critical nature, the waterproofing aspect of façades is often overlooked when it comes to designing and constructing buildings. Not only does this put buildings and occupants at risk, it also can result in costly construction delays, repairs, and more frequent maintenance.

What have the drawings missed?

A building’s plans and drawings can show you a lot – but not everything. And, in the construction industry, getting it wrong is incredibly unforgiving.

In the concept stage, an architect will typically use a cross-section and/or typical detail on the drawing to show how the façade is to be constructed. However, what may look like just two lines intersecting on the plan is an area that will need more consideration on how that transition or termination needs to be waterproofed – particularly if a horizontal plane is connecting a vertical one or two different materials will be touching.

In short, seeing a potential leak on a drawing is tough!

That’s where experience and having your façade and waterproofing specialists involved from the start is so important.

A recent example is a large building we were asked to get involved with after the previous contractor had abandoned the job. Since a façade expert hadn’t provided advice and guidance at the design stage, the contractor couldn’t successfully waterproof the façade and didn’t have the necessary experience to solve the challenges with the design.

When we got involved, unfortunately, construction had progressed to a stage where the necessary repairs, alterations, and fixes could no longer be implemented without amending the building consent and redesigning the waterproofing methods for a substantial portion of the façade. This approach made the application more difficult and riskier and increased the likelihood of earlier maintenance, repeated replacements, and weathering issues.

Ultimately, not getting these issues sorted at the design stage and appointing the correct waterproofing contractor delayed the building’s completion date by at least three months and incurred significant extra costs for the developer, not to mention the ongoing maintenance.

Damaged materials – happens more often than you think

While it might initially sound surprising, considering how building materials may have to travel to site and the sheer number of people and activity that happens on a construction site, it is actually relatively common for damage to occur.

This is something that is never really considered until you have damaged materials turn up on site.

The installation of precast panels is a great example. These panels have lifting eyes incorporated within them, typically located in the area where waterproofing, sealing, or jointing takes place. When the panels are lifted during installation, it is crucial to reinstate the lifting eyes in their designated positions. However, the areas around these lifting eyes can get damaged due to tight tolerances or mishandling during transportation.

Transportation limitations sometimes lead to unconventional positioning of the panels. For instance, panels may be loaded sideways on a truck and then rotated into position during installation. This change in orientation means that the lifting eyes, which were originally designed to only be on the top of the panel also ended up on the side.

Protecting your building when its most vulnerable

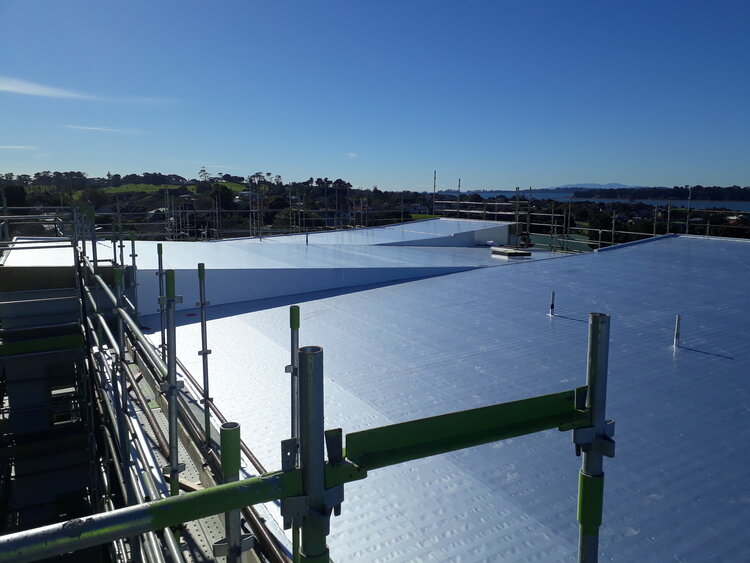

During construction, a structure is at its weakest, lacking essential drainage, roofing, and façade elements, making it vulnerable to weather events.

As we’ve been reminded lately, you can’t predict the weather. Therefore, buildings should be temporarily waterproofed throughout the construction process. This way, the interior works can proceed in the lower stages of the building while the upper elements remain exposed and incomplete.

We recently were involved in a project where we installed temporary waterproofing on multiple levels of a building. However, as the project neared its final stages, the client made a commercial decision to forgo the final level that was scheduled for temporary waterproofing. As this was prior to the roof being installed, that unprotected level was exposed and vulnerable.

Unfortunately, the rain came and the building experienced significant flooding.

We received desperate calls for assistance in the midst of the rain, but it was too late.

What had initially looked like a cost-saving measure on paper quickly turned into an expensive disaster.

Experience

To make sure things aren’t missed at the design phase, façade materials are handled and installed correctly, and the building is watertight during construction, we approach things a little differently at Sansom.

We like to be involved right from the start, using our experience and expertise to guide projects from the initial design phase all the way through to the end, avoiding pitfalls that could delay construction, incur extra cost or require ongoing maintenance.

By pre-emptively considering potential issues, we ensure everyone involved has the necessary knowledge and means to swiftly address any problems that may arise. This is particularly crucial in the case of building façades, as their construction process is generally quick, adhering to a tight programme. By anticipating and accounting for these challenges in advance, we can react quickly and seamlessly, ensuring the project progresses smoothly.

Our approach not only solves short-term problems but also prevents ongoing long-term challenges that impact other stakeholders down the line.

Throughout, our industry-best quality assurance measures provide peace of mind for ourselves, the architect and building owner.

We sign producer statements and obtain warranties from our suppliers for the materials we use. As approved applicators, we provide quality assurance to our suppliers, who are invited to witness our on-site construction process.

To make it easy for main contractors and clients to verify construction details, we don’t use paper-based systems. Instead, all data is inputted into CONQA, an online quality assurance system, including site inspections and observations by our façade team to create a comprehensive set of live compliance documentation.

The fact that despite the recent weather events, Sansom has had no callbacks about leaking buildings, shows that our approach to façades works.

So, get in touch to start the conversation about your upcoming project: sansom.co.nz/contact-us/